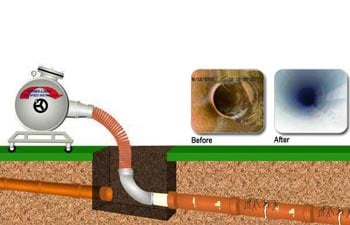

A cured-in-place pipe (CIPP) is a trenchless rehabilitation method used to repair existing pipelines. It is a jointless, seamless pipe lining within an existing pipe. As one of the most widely used rehabilitation methods, CIPP has applications in sewer, water, gas, and chemical pipelines. The Bluelight LED system has revolutionized the CIPP lining process, especially for laterals and small sewer pipes 4 to 24″ in diameter. While traditional CIPP lining systems use epoxy resins cured with steam, hot water or ambient air, the Bluelight System uses specially-formulated resin that cures with LED light. The primary advantage of the Bluelight system is the speed at which it cures – up to 5 times faster than conventional curing methods.

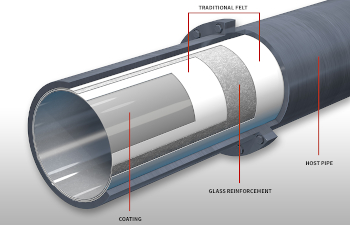

The process of CIPP involves inserting and running a felt lining into a preexisting pipe that is the subject of repair. Resin within the liner is then exposed to a curing element to make it attach to the inner walls of the pipe. Once fully cured, the lining now acts as a new pipeline.